If you’re working with drilling operations in India, choosing between OCMA bentonite grades can feel like navigating a maze. I’ve been there too staring at technical specifications, wondering which API 13A standard will give you the best results for your specific drilling project. The truth is, both Section 10 and Section 9 have their place in the drilling industry, but knowing when to use which one can make or break your operation’s efficiency.

In this blog, I’ll break down everything you need to know about these two critical drilling mud standards, so you can make informed decisions that save both time and money.

Understanding OCMA Bentonite Grades and Their Importance

Before we dive into the comparison, let’s get our basics right. OCMA stands for the now-defunct “Oil Company Materials Association,” but the standards they established continue to guide the industry today. These standards have been integrated into the American Petroleum Institute (API) specifications, specifically API 13A, which governs drilling fluid materials. OCMA bentonite is an activated grade of sodium bentonite with unique functions that make it invaluable for drilling operations. Think of bentonite as the backbone of your drilling mud system. Without the right grade, you’re essentially trying to build a house without proper foundation materials.

The clay’s ability to swell, create viscosity, and form protective barriers in the borehole determines whether your drilling operation runs smoothly or faces costly complications.

API 13A Section 9: The Standard Workhorse

API 13A Section 9 represents the standard specification for drilling-grade bentonite. Sodium Bentonite meets API specifications 13A section 9 as a premium-grade sodium montmorillonite clay, used as primary filter-cake building, filtration-control and suspension agent in water-base mud systems.

Key Characteristics of Section 9 Bentonite

Viscosity Properties

- Provides reliable viscosity enhancement in water-based drilling fluids

- Creates stable gel structures that support drilling operations

- Maintains consistent performance under standard drilling conditions

Filtration Control

- Builds effective filter cakes to prevent fluid loss

- Reduces formation damage during drilling

- Maintains borehole stability through controlled fluid invasion

Cost-Effectiveness Section 9 grade offers excellent value for money, making it the go-to choice for standard drilling operations where extreme conditions aren’t expected.

Applications Where Section 9 Excels

- Routine water well drilling

- Standard oil and gas exploration

- Projects with moderate depth requirements

- Operations in stable geological formations

API 13A Section 10: The High-Performance Solution

Section 10 takes bentonite performance to the next level. API13A Section 10 provides the construction solution of sealing drill holes to prevent cavities and leakages.

This grade is specifically designed for more demanding applications where standard bentonite might fall short.

Key Characteristics of Section 10 Bentonite

Enhanced Sealing Properties

- Superior hole sealing capabilities

- Better prevention of fluid migration

- Improved cavity stabilisation

Higher Performance Standards

- Tighter quality control specifications

- Enhanced purity levels

- Consistent performance under challenging conditions

Advanced Applications

- Deep drilling operations

- High-pressure environments

- Critical sealing applications

- Complex geological formations

When Section 10 Makes Economic Sense

While Section 10 costs more upfront, it often pays for itself through:

- Reduced drilling complications

- Lower fluid loss rates

- Decreased formation damage

- Improved overall drilling efficiency

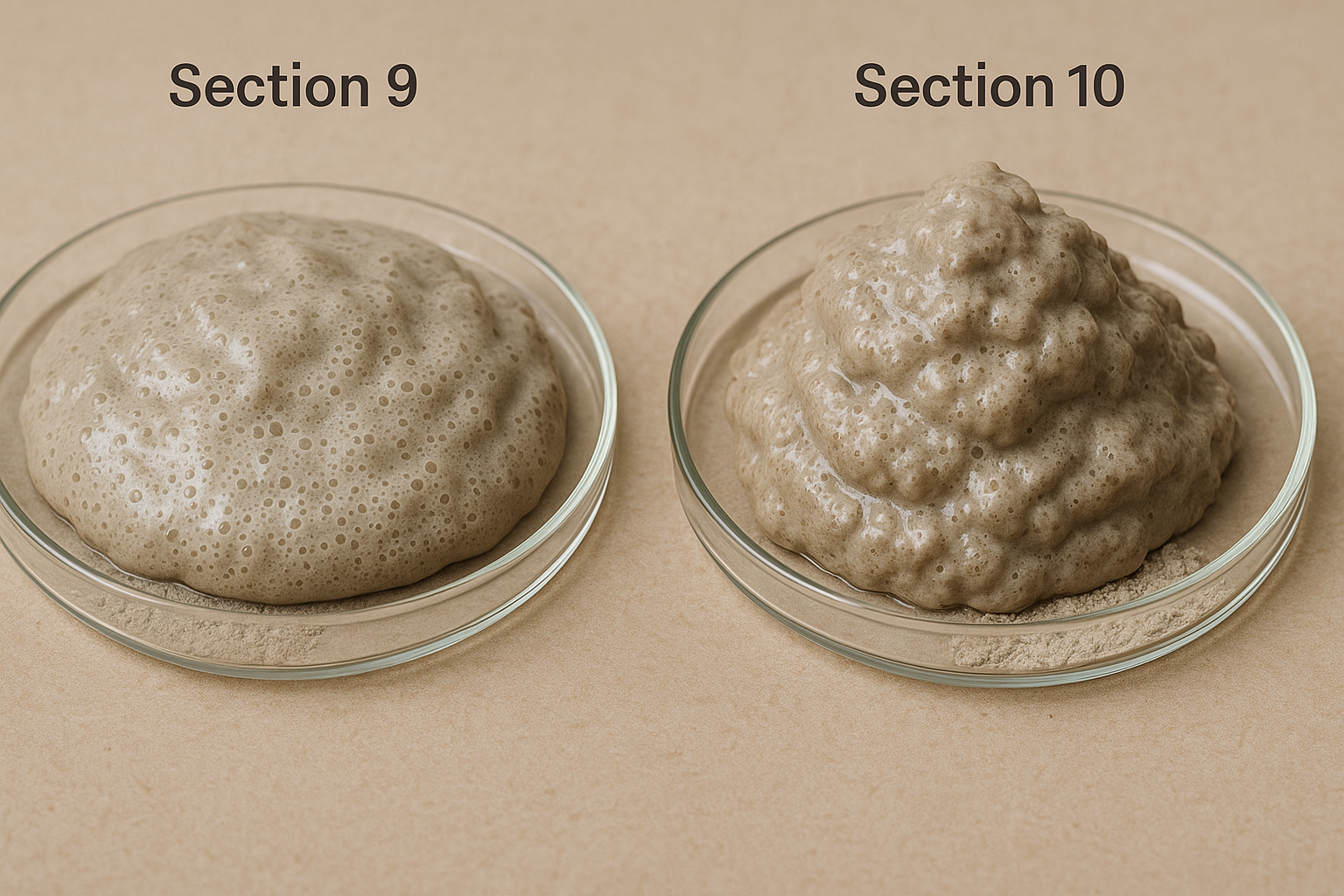

Head-to-Head Comparison: Section 9 vs Section 10

Performance Metrics

Viscosity Development

- Section 9: Adequate for most applications

- Section 10: Superior viscosity characteristics with better stability

Filtration Control

- Section 9: Good filtration control for standard operations

- Section 10: Excellent filtration control with enhanced sealing

Quality Consistency

- Section 9: Reliable quality within standard parameters

- Section 10: Tighter quality control with premium consistency

Cost Considerations

Initial Investment Section 9 typically costs 15-25% less than Section 10, making it attractive for budget-conscious projects.

Section 10’s higher price reflects its enhanced processing and tighter quality specifications.

Total Cost of Ownership However, when you factor in potential drilling complications, fluid losses, and operational delays, Section 10 often delivers better value in challenging applications.

Application Suitability

Choose Section 9 When:

- Working with standard drilling conditions

- Budget constraints are primary concern

- Drilling in well-understood formations

- Operating at moderate depths and pressures

Choose Section 10 When:

- Dealing with complex geological conditions

- Drilling at significant depths

- Working in high-pressure environments

- Sealing integrity is critical

- Operating in sensitive environmental areas

Real-World Application Examples

Let me share some scenarios where the choice between these grades made a significant difference.

Case Study 1: Water Well Drilling in Rajasthan A contractor initially chose Section 9 for a series of water wells. While the grade performed adequately, they experienced some fluid loss issues in certain formations. Switching to Section 10 for similar conditions resulted in 30% better hole stability and reduced drilling time.

Case Study 2: Oil Exploration in Gujarat An exploration company used Section 10 for deep drilling operations in challenging formations. The enhanced sealing properties prevented costly fluid losses and maintained borehole integrity throughout the operation. The additional cost was offset by improved drilling efficiency and reduced complications.

Factors Influencing Your Choice

Geological Conditions

Formation Stability Unstable formations benefit significantly from Section 10’s superior sealing properties. Stable formations may work perfectly well with Section 9.

Permeability Levels High-permeability formations require the enhanced filtration control that Section 10 provides.

Operational Parameters

Drilling Depth Deeper wells generally benefit from Section 10’s enhanced performance characteristics. Shallow to moderate depths often work well with Section 9.

Pressure Conditions High-pressure environments favour Section 10’s superior stability.

Economic Factors

Project Budget Section 9 offers cost advantages for projects with tight budgets. However, consider the total cost of ownership, not just initial material costs.

Risk Tolerance If drilling complications could be catastrophic, Section 10’s reliability premium is worthwhile.

Making the Right Choice for Your Project

Here’s my practical framework for choosing between these grades:

Step 1: Assess Your Operating Conditions

- Formation characteristics

- Drilling depth

- Pressure expectations

- Environmental sensitivity

Step 2: Evaluate Risk Factors

- Cost of potential complications

- Timeline sensitivity

- Regulatory requirements

- Safety considerations

Step 3: Calculate Total Cost Impact

- Material costs

- Potential delay costs

- Complication mitigation expenses

- Long-term operational efficiency

Step 4: Consider Supplier Reliability

Working with established suppliers like those in India’s bentonite industry ensures you get consistent quality regardless of which grade you choose.

Industry Trends and Future Considerations

The drilling industry is moving towards more demanding applications, which generally favours higher-performance materials like Section 10.

Environmental Regulations Stricter environmental standards often require the enhanced sealing capabilities of Section 10.

Technology Advancement Modern drilling techniques frequently push the boundaries of what standard materials can handle.

Cost-Benefit Analysis Evolution As drilling operations become more sophisticated, the total cost of ownership becomes more important than initial material costs.

Expert Recommendations

Based on my experience in the industry, here are my recommendations:

For Standard Operations Section 9 remains an excellent choice for routine drilling where conditions are well-understood and predictable.

For Critical Applications Section 10 provides the performance reliability that critical operations demand.

For Mixed Operations Consider maintaining inventory of both grades to optimise costs while ensuring performance when needed.

Quality Assurance and Testing

Regardless of which grade you choose, ensure your supplier provides:

- Comprehensive testing certificates

- Consistent quality documentation

- Technical support for application guidance

- Reliable supply chain management

Conclusion

The choice between API 13A Section 10 and Section 9 isn’t about one being universally better—it’s about selecting the right grade for your unique needs. CMS Industries recommends aligning performance characteristics with your specific operating conditions. Section 9 delivers reliable, cost-effective results for standard applications, while Section 10 offers enhanced capabilities for demanding environments where higher performance justifies the added cost. CMS Industries advises evaluating your geological conditions, operational parameters, risk tolerance, and total cost of ownership. Remember, choosing the right bentonite grade from CMS Industries is an investment in long-term operational efficiency not just a material purchase.

Whether you choose Section 9 or Section 10, partnering with experienced suppliers ensures you get the quality and support needed for successful drilling operations using the right OCMA bentonite grades for your specific drilling mud standards.

Frequently Asked Questions

Q:1 What is the main difference between API 13A Section 9 and Section 10 bentonite?

Section 10 offers enhanced sealing properties and superior filtration control compared to Section 9, making it suitable for more demanding drilling conditions and critical sealing applications.

Q:2 Is Section 10 bentonite always better than Section 9?

Not necessarily. Section 9 is perfectly adequate for standard drilling conditions and offers better cost-effectiveness. Section 10 is better for challenging environments where superior performance is essential.

Q:3 How much more expensive is Section 10 compared to Section 9?

Section 10 typically costs 15-25% more than Section 9, but this premium often pays for itself through improved operational efficiency and reduced complications.

Q:4 Can I use Section 10 bentonite for all my drilling applications?

Yes, you can use Section 10 for all applications, but it may not be cost-effective for routine operations where Section 9 would perform adequately.

Q:5 Which grade should I choose for deep water well drilling?

For deep water well drilling, Section 10 is generally recommended due to its superior sealing properties and enhanced performance under challenging conditions that typically occur at greater depths.