Choosing the right drilling fluid can make or break a water well project. The type of bentonite you use affects everything from borehole stability to how efficiently you remove cuttings. While both sodium and calcium bentonite come from the same clay mineral family, their performance in water well drilling differs significantly.

Let’s break down which type delivers better results for water well applications and why it matters.

What Makes Sodium and Calcium Bentonite Different?

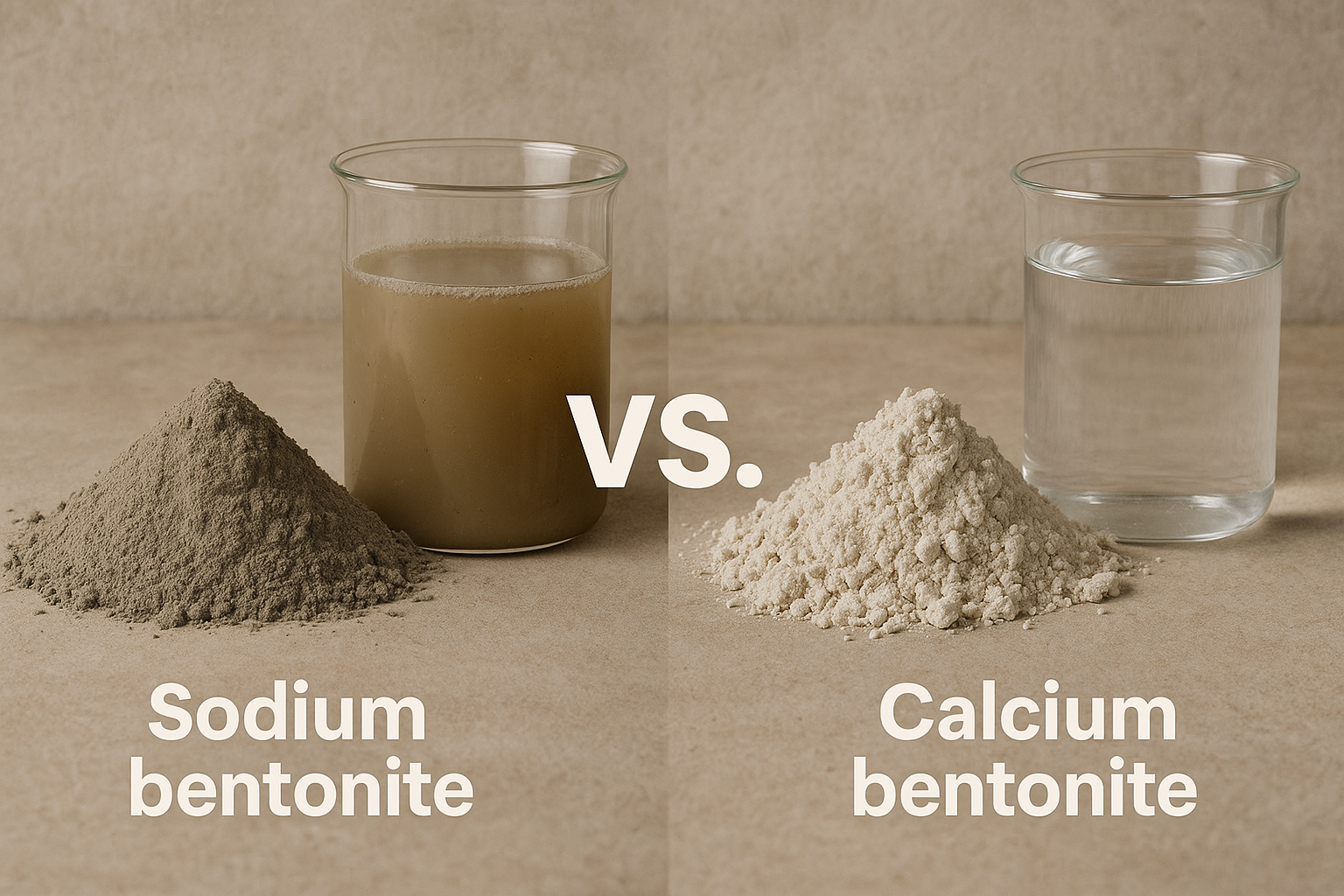

Both types start as montmorillonite clay, but the dominant exchangeable cation creates distinct characteristics. Sodium bentonite contains primarily sodium ions, while calcium bentonite has calcium ions in its structure. This single chemical difference changes how each type behaves when you add water.

Sodium bentonite can expand up to fifteen times its original volume when mixed with water. This swelling capacity is what makes it stand out. Calcium bentonite, by comparison, has much lower swelling ability. It absorbs water but doesn’t create the same thick, gel-like consistency that drilling operations need.

The swelling happens because sodium ions allow the clay platelets to repel each other and separate when hydrated. Calcium ions, being divalent, tend to link the platelets together instead of pushing them apart. This fundamental difference determines which type works better for specific applications.

Why Water Well Drilling Needs High Swelling Capacity

Water well drilling demands a drilling fluid that performs multiple jobs at once. You need it to carry cuttings to the surface, create a stable mud cake on the borehole walls, prevent collapse, and cool the drill bit. All of these functions depend on the fluid’s viscosity and gel strength.

Sodium bentonite excels here because its high swelling capacity creates the thick, viscous fluid required for these tasks. When properly mixed, it forms a suspension that keeps cuttings in place even when circulation stops. This prevents the drill string from getting stuck when you add another length of pipe.

The mud cake formation matters just as much. As sodium bentonite contacts the formation, it creates a thin, impermeable layer that seals porous zones and prevents fluid loss into the formation. This cake also stabilizes unconsolidated formations that might otherwise cave into the borehole.

Calcium bentonite simply can’t match these properties. Its lower swelling capacity means you’d need to use much more material to achieve similar viscosity levels. Even then, the gel strength and filtration control won’t be as effective as what sodium bentonite provides.

Sodium Bentonite vs Calcium Bentonite: Performance Comparison

Here’s how the two types stack up for water well drilling:

- Swelling and Viscosity Sodium bentonite creates higher viscosity with less material. You typically need only 5-7% by weight to achieve proper drilling fluid properties. Calcium bentonite requires significantly more product to reach minimum viscosity standards, making it less economical for drilling operations.

- Gel Strength The ability to suspend cuttings when circulation stops depends on gel strength. Sodium bentonite develops strong thixotropic properties, meaning it gels quickly when at rest but flows easily when agitated. Calcium bentonite forms weaker gels that may not adequately suspend heavy cuttings.

- Filtration Control Sodium bentonite creates a tight, thin filter cake that minimizes fluid loss into formations. This prevents formation damage and maintains borehole pressure. Calcium bentonite produces thicker, more permeable filter cakes that allow greater fluid loss.

- Water Quality Sensitivity Here’s where things get tricky. Sodium bentonite performs best in fresh water with low dissolved solids. Hard water containing calcium or magnesium can cause the sodium bentonite to flocculate, reducing its effectiveness. Calcium bentonite is already calcium-saturated, so hard water doesn’t degrade its performance as dramatically.

When Sodium Bentonite is the Clear Winner

For most water well drilling projects, sodium bentonite is the better choice. Its superior swelling capacity and rheological properties make it the industry standard for good reason.

- Drilling Through Unstable Formations When you’re drilling through loose sand, gravel, or fractured rock, you need maximum borehole support. Sodium bentonite provides the viscosity and gel strength to prevent caving and hold the hole open between drilling passes.

- Deeper Wells As well depth increases, so do the demands on your drilling fluid. Sodium bentonite maintains its properties under the higher temperatures and pressures found in deeper formations. It also suspends cuttings more effectively over longer distances.

- Faster Drilling Rates The excellent rheological properties of sodium bentonite allow for higher penetration rates. The fluid efficiently removes cuttings from the bit face and carries them to the surface without excessive pump pressure.

CMS Industries manufactures high-quality sodium bentonite specifically formulated for water well drilling applications. Their products meet API standards for viscosity and filtration control, ensuring reliable performance across different geological conditions.

Wondering how calcium bentonite differs from paper bentonite? Read this blog to discover which one’s better for eco-friendly applications!

The Role of Water Chemistry in Bentonite Selection

Water quality can make or break your drilling fluid performance. This is where understanding your mix water becomes critical.

If your water source has high calcium content, hardness, or low pH (below 8), sodium bentonite won’t hydrate properly. The calcium ions in hard water disrupt the ionic charge of the bentonite platelets, causing them to clump together rather than disperse. This flocculation destroys the fluid’s viscosity and suspending properties.

In these situations, you have three options:

- Treat the water to remove hardness before mixing

- Add soda ash or other chemicals to sequester the calcium

- Consider whether calcium bentonite might work for shallow, less demanding applications

The third option is rarely ideal for water well drilling, but in situations with extremely hard water and shallow depths, it might be worth evaluating. Water makes up 95-99% of your drilling fluid, so testing and treating your mix water often solves problems attributed to the bentonite itself.

Cost Considerations and Material Efficiency

While sodium bentonite typically costs more per bag than calcium bentonite, it’s more economical in practice. You need far less sodium bentonite to achieve the required fluid properties.

A typical sodium bentonite might yield 90-100 barrels of drilling fluid per ton of material. Calcium bentonite might only yield 20-30 barrels per ton. When you factor in the amount needed, transportation costs, and handling time, sodium bentonite usually costs less overall.

The reduced material usage also means less storage space on the drill site and fewer bags to handle. These operational efficiencies add up quickly on larger projects.

Special Applications for Calcium Bentonite

Calcium bentonite does have legitimate uses, just not typically in water well drilling. Its high adsorption capacity makes it valuable for other applications:

- Wine clarification and beverage processing

- Pet litter and animal bedding

- Detoxification and health products

- Wastewater treatment

Some drilling contractors use calcium bentonite in very shallow boreholes where the lower viscosity requirements make it adequate. However, this is the exception rather than the rule.

The ability to convert calcium bentonite to sodium bentonite through chemical treatment exists but adds complexity and cost that defeats the purpose of using the less expensive material.

Quality Standards and Product Selection

Not all sodium bentonite is created equal. The American Petroleum Institute (API) sets standards for drilling-grade bentonite that specify minimum performance criteria.

According to API standards, bentonite should produce an apparent viscosity of at least 15 mPas when dispersed at approximately 6% concentration in fresh water. Premium or high-yield sodium bentonite exceeds these minimum standards.

When selecting bentonite for water well drilling, look for products that specify:

- API 13A compliance

- Yield measurements (barrels per ton)

- Viscosity specifications

- Filtration loss data

- Swelling index values

CMS Industries produces multiple grades of bentonite powder and lumps, with their sodium bentonite grades specifically engineered for drilling applications. Their ISO 9001:2015 certification ensures consistent quality control across production runs.

Mixing and Handling Best Practices

Getting the best performance from sodium bentonite requires proper mixing technique. The clay needs sufficient time and energy to fully hydrate.

Mix bentonite thick initially – a full bag in a 55-gallon drum of water works well. Let it hydrate for at least 6-8 hours before use if possible. You can then dilute it to the desired viscosity by adding water once it’s in the mud pits.

This method achieves better dispersion than trying to mix directly to the target viscosity. The thick initial mix ensures the platelets separate fully before dilution.

Avoid adding bentonite too quickly to the mix water. Rapid addition creates “fish eyes” – clumps of dry bentonite surrounded by hydrated material. These clumps won’t break down and represent wasted material.

Temperature affects hydration time. Cold water requires longer mixing periods, while warm water speeds hydration. Some contractors heat their mix water during winter operations to improve bentonite performance.

Curious about water well drilling bentonite? Read this blog to learn what it is and how it works to make drilling more efficient!

Making the Right Choice for Your Project

For water well drilling, sodium bentonite is almost always the right answer. Its superior swelling capacity, viscosity, and filtration control make it the industry standard for good reason.

The only time to consider calcium bentonite is when dealing with extremely hard water in very shallow, non-critical boreholes. Even then, treating your water and using sodium bentonite usually gives better results.

Pay attention to your water quality. Test the hardness, pH, and dissolved solids before assuming your drilling fluid problems come from the bentonite. Good sodium bentonite mixed with bad water will perform poorly, while even premium bentonite can’t overcome severe water quality issues without treatment.

Choose a reliable supplier that can provide consistent quality and technical support. The drilling fluid is too critical to the success of your project to compromise on material quality.

Connect with Quality Bentonite Solutions

Selecting the right bentonite and sourcing it from a reliable manufacturer makes a measurable difference in drilling efficiency and project success. CMS Industries specializes in producing premium sodium bentonite for water well drilling and other applications.

With strategically located manufacturing facilities near major ports in Gujarat, they serve drilling operations across the globe. Their product range includes various grades of bentonite powder and lumps, all produced under ISO 9001:2015 certified quality systems.

Whether you’re drilling shallow domestic wells or deep commercial projects, partnering with a manufacturer who understands the technical demands of your application ensures you get material that performs when it matters. Visit CMS Industries to learn more about their sodium bentonite products and how they can support your water well drilling projects.

Frequently Asked Questions

What is the main difference between sodium bentonite and calcium bentonite for drilling?

Sodium bentonite swells up to fifteen times its volume when mixed with water, creating the high viscosity and gel strength needed for drilling operations. Calcium bentonite has much lower swelling capacity and can’t achieve the same fluid properties, making it unsuitable for most water well drilling applications.

Can I use calcium bentonite instead of sodium bentonite to save money?

While calcium bentonite costs less per bag, you need three to four times as much to achieve similar viscosity. It still won’t match sodium bentonite’s gel strength or filtration control. For water well drilling, sodium bentonite is more economical despite the higher unit price.

Why does my sodium bentonite clump instead of mixing smoothly?

This usually indicates hard water with high calcium content. Calcium ions cause bentonite platelets to flocculate rather than disperse. Test your mix water and treat it with soda ash or other sequestering agents to remove hardness before mixing bentonite.

How much sodium bentonite do I need for a typical water well drilling project?

Most drilling operations use 5-7% bentonite by weight in their drilling fluid. A typical high-yield sodium bentonite produces 90-100 barrels of fluid per ton of material. Your specific needs depend on formation characteristics, well depth, and drilling conditions.

Does bentonite type affect the quality of the completed water well?

The drilling fluid itself doesn’t remain in the well after completion and development. However, sodium bentonite’s superior filtration control creates thinner filter cakes that are easier to remove during well development, potentially resulting in better well performance and higher yields.